With almost 70% of direct garment cost in textile products coming from raw materials, finding the structure that delivers the lowest cost when sourcing textiles and apparel can be challenging. Many mills operate with horizontal integration, and others have taken a vertically integrated approach. Each of the two approaches has pros and cons to importers…

Textile And Apparel Sourcing Challenges in the Global Economy

The shift to the global economy of the last few decades has been dramatic. And although many complex factors have driven this change, it is safe to say that cost has been the key factor in many company’s decisions to import raw materials or to manufacture in low-cost regional markets.

The result has been a shift in both retail and manufacturing trends worldwide. But as the global economic model has matured, it has become apparent that for many industries the shift to offshoring of raw materials, components and finished goods has brought challenges to the “low-cost at all cost” model.

Exploring Vertical VS Horizontal Integration In Textile Mills

Let’s look in more detail at the pros and cons of each type of integration to importers engaged in textile and apparel sourcing.

Vertically Integrated Textile Mills

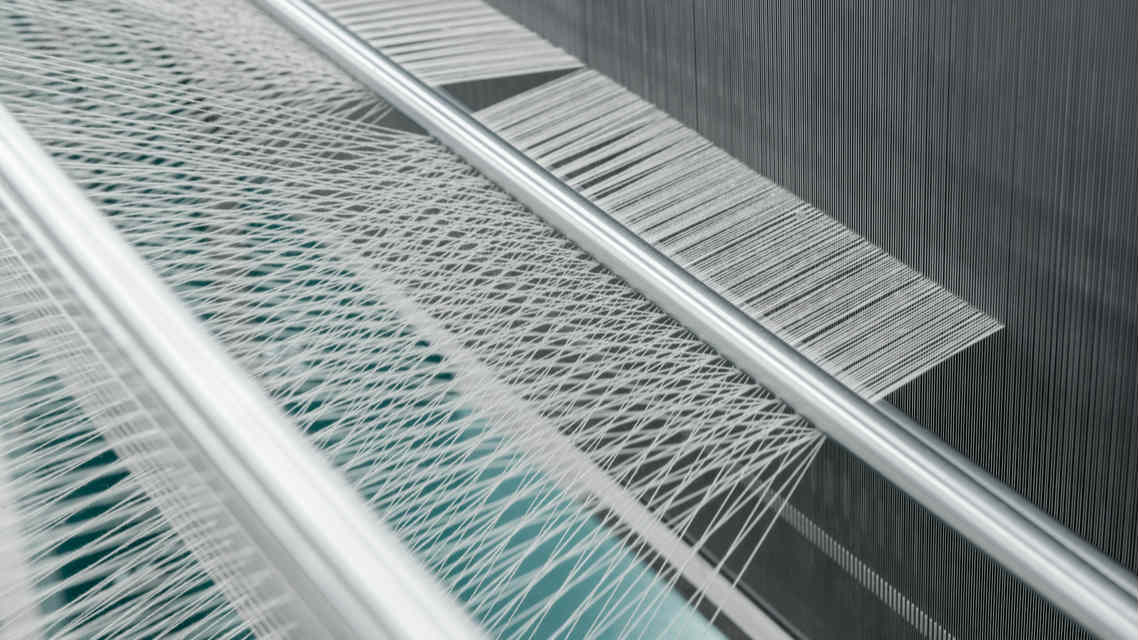

In vertically integrated mills production is managed from start to finish with mills conducting the yarn prep such as carding, drawing and spinning, all the way through weaving/knitting and the dying and finishing of apparel.

This approach provides several advantages and disadvantages:

Pros

- Smoothen the supply chain. The production process is under control of operators and managers qualified and familiar with that company’s products.

- Increase entry barriers for new entrants.

- Time constraints are predictable and therefore can be planned for scheduling.

- Quality can be built into the process to ensure repeatability for quality standards as well as to include quality in the overall cost structure as the product is made rather than a more expensive process of end quality checks after production is finished.

- Compliance issues and sustainability can be controlled in all production phases.

Cons

- Less flexible. As companies strive to supply an economy of scale, the ability to increase or decrease the production of raw materials may be lost.

- Capital investment costs in machinery and equipment are extensive.

- Capacity is fixed, and a large surge in order position can pose production constraints.

- Lot size is less flexible and geared more toward higher volume goods.

- Because capital expense is tied up in acquiring and maintaining equipment, additions of new technology must be reviewed through the lens of short-term ROI.

Horizontally Integrated Textile Mills

In horizontally integrated mills fabric is often purchased in greige form and “prepared for dying” (PFD) fabric is produced by a different entity or by several entities. These fabrics are often delivered to a single center for dying and then sub-contracted out to other converters/finishers for printing or finishing, and may even be sent to an additional vendor for packing.

Pros

- Production requirements can be highly flexible to take advantage of lower cost as well as a sudden expansion or retraction in order position.

- Seasonal or “viral” trends in the market can be responded to quickly with last-minute developments and production for niche or “trending” items.

- A higher degree of innovation.

Cons

- Quality is often not under close enough control for all phases of production.

- Price is often the driving force of raw material acquisition at the expense of quality.

- Compliance and sustainability are not well controlled.

- Traceability and tracking of origin and production lots are difficult.

Risks & Control Issues Related To Horizontal Integration

Horizontal integration can give a company an economy of scale and leverage with vendors and suppliers on price, but it does not address many key issues impacting today’s markets.

This leaves the loop on traceability open and susceptible to vendor and supplier variances in key raw materials and components as the buyer remains focused simply on more market and lower cost without necessarily building stronger vendor compliance and control.

And while control can be established through testing of the final product, the lack of traceability down to the lot can prove more costly, generate more waste and exacerbate compliance and sustainability due to the reactive testing measures that must be taken and the information, such as lot traceability, which may be lost prior to testing.

Some examples of textile and apparel quality issues affected by lack of traceability may include:

- Process variations for raw materials from one vendor to another may affect production quality in the garment manufacturing location where they are consumed.

- Regional and therefore climate-related variations in natural fibers can result in variations in performance characteristics for the same specification of fabric produced by different suppliers. These variations may cause yarn issues such as slubs, twist variations, coarseness and other yarn characteristics which may affect the fabric at the weaving or knitting phase.

- Manmade fibers such as polypropylene may exhibit different characteristics vendor to vendor depending on the percent of reworked material processed through the extrusion process.

- Age of processing equipment and the number of process steps among vendors may lead to like products performing with slightly different characteristics such as temperature or elongation or other properties. For example, a lack of a sanforizing process can result in differential shrinkage, skewing, bow and bias that may manifest itself after cut and sew.

- Shade variation due to the method of manufacture or contamination issues can result in a company’s inability to mix presumably identical materials in production.

How Vertical Integration Succeeds Over Horizontal

In Vertical Integration, the company that owns and controls the factories and sources of material and controls may control other aspects of the supply chain such as logistics and distribution¹.

In this type of integration, the parent company controls all phases of production from the inception of design through raw materials, production, and post-processing.

By possessing this level of control, the company can require traceability for its apparel products from the initial manufacture of raw materials through to the final product. This can help address two very important issues:

- Compliance: Textile and apparel companies that have moved to vertical integration can build their compliance into the supply chain from beginning to end. This allows them to incorporate the cost of compliance into their product cost at all levels of production and distribution.

- Quality: As important as compliance, quality in vertically integrated companies allows tight testing and quality control throughout the process. As the company owns or controls each phase of the product production chain, quality can be monitored and confidently certified at each phase.

In the event of a quality failure, earlier detection can reduce the cost of non-conformance as a direct cost as well as protect indirect costs that could accrue to the brand name had the product suffered quality failure in the field in the hands of the consumer.

What Next If Your Supply Chain Is Horizontally Integrated?

For companies using a horizontally integrated approach when sourcing apparel or textiles, there are solutions that can help reduce the risk and mitigate specific end-product quality concerns. And global companies with large production volumes and diverse and extensive product offerings have higher motivation and vested interest in controlling and monitoring their raw material supply to control both quality and cost.

Many quality testing and audit companies, like SgT, exist that can assist a company in developing a proactive plan for managing the risks caused by horizontal integration of their raw material and production. Some of the key benefits include:

- Auditing textile mills the parent company uses as raw material suppliers. These audits help understand the overall supply chain organization of tier two and tier one aspects of production.

- Supplier mills can be assessed using these audits to understand the mill’s capabilities and identify areas of concern and corrective action either at the mill or in prep for incoming deliveries from the supplier mill.

- Corrective and preventive action plans can be developed to bring suppliers into compliance in early-stage production. This maintains the integrity of the supply chain and helps assure critical data such as sustainability, and lot information is traceable.

- Support mills, buyers and brands to understand their core strengths and identify their weaknesses.

- Early investment in such audit, assessment and corrective action plans will reduce waste and product quality failures at later stages.

While sourcing in the global economy will remain cost-driven for the near term, evolving dynamics and trends seem to dictate that they won’t always be exclusively so.

Consumer tastes and increasing global concerns have posed a challenge to horizontally integrated companies to include and invest in resources to properly test, quality manage and trace production to improve overall accountability.

Your View…

How are costs in your supply chain affecting you today? Are you wrestling with a horizontally integrated supply chain, or is your sourcing and production more tightly controlled?

Please share your experiences, or ask any questions you may have on this topic by leaving a comment below. We are on hand to answer you.

{{cta(‘df2514bd-21b2-4dd1-a2bb-65d0f0235488’)}}

¹ “Fast Fashion in a Flat World: Global Sourcing Strategies”, by Barbara Mihm, University of Wisconsin, International Business and Economics Research Journal, June 2010, Volume 9 Number 6