Your brand could be collaborating with the best manufacturer in the market, but if your raw materials or trim supplies are substandard, you won’t be exempt from experiencing major quality issues during the final stages of production.This blog post will shed some light on why ensuring the quality of raw materials coming in through raw material inspections should be one of the first critical steps in your manufacturing process.

Textile Raw Material Inspections

In the apparel industry, the quality of the finished product is directly related to the quality of the fabric when it is received as a roll. Even if your manufacturer works with state-of-the-art equipment and utilizes the most outstanding manufacturing methods, it will not counterbalance the effects of using defective, non performing or non compliant raw materials.

Many factories in the textile industry experience quality issues with their final products as a result of inadequate raw materials passed down the production line. What some factory managers often may not realize is that these problems are easily avoidable. Therefore, quality management of raw materials should be embedded in the development stage and is crucial for avoiding any costly quality issues further down the line. Quality and compliance of raw materials are essential for ensuring supply chain organization and decreasing potential quality risks later during production. This can be done through implementing effective quality management systems which will significantly improve operational performance, as well as save valuable time and money leading to higher quality goods and increased profitability. Quality management of the development stage is the most crucial step of the manufacturing process. Ensuring that the right products are produced using high-quality materials will reduce quality risks by as much as 70%!

There are various types of textile raw materials inspections that are applied in the garment industry:

The 4-Point System

A visual defect assessment is conducted on between 10% – 50% of the produced products where visible flaws such as stains, stitching, incorrect color variations, patterns, sizes, and poor alignment, etc. are tested. To do this, a grading system should be specified together with the level of acceptance. The 4-Point System is also referred to as the American Apparel Manufacturers (AAMA) point-grading system for determining fabric quality and is the most widely used grading system in the apparel industry.

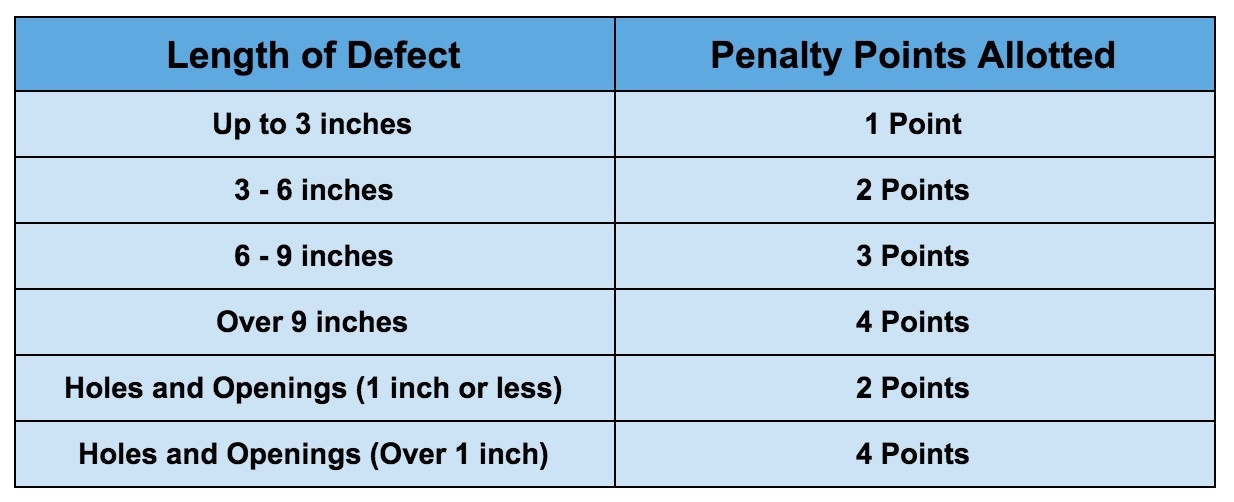

1, 2, 3 and 4 penalty points are assigned to each product either length or width direction according to the size and significance of the defect, not exceeding a point of 4 for a single error. The 4-Point system requires that no less than 10% of the total rolls in the shipping container may be tested, ensuring that at least one roll of each color scheme is examined.

The 4-Point System assigns defects based on the following criteria:

Source: Garment Raw Material Inspection

Defect points are calculated per 100 square yards of fabric, and no more than 40 penalty points are generally accepted. No penalty points will be assigned to minor defects and any continuous defect should be allocated a maximum of 4 points for every yard or meter within the shipment.

The formula to calculate penalty points per 100 square yards is given by:

= (Total points scored in the roll * 3600) / Fabric width in inches * Total yards inspected

Conformity Tests

Inspections are conducted to examine the conformity of the product based on the designs, dimensions, colors, raw materials, weaving, knitting, shading, tannings, finishings, coating, etc. This is achieved by comparing the finished product to the Pre-Production Sample (PPS), other technical files, and product specifications which you have agreed upon with your suppliers in advance.

Additional Textile Raw Material Inspections

The fabric is the main element of the garment. Therefore, the quality of the material should be carefully judged at the seller’s factory before the purchase is made, and more specifically the product. The risk of producing garments made of low-grade fabrics is too high to forgo raw material inspections. A sewing thread inspection is critical as it directly impacts the quality of the garment. Sewing threads run through needles at speeds of 140 to 165 km per hour, which can significantly decrease the strength of the thread. Therefore, the thread size and sewability should be checked. To avoid any potential issues with the chains/zipper of the garment, the following should be verified beforehand as the garment will be completely unfit for wearing if the zipper is faulty; dimension, stops, puckering, slider, lock, arrow mark, uniform color, etc.

The importance of raw material checks can’t be denied. Many brands make use of textile quality management solution providers, who are experts in the industry and can guide you through the entire process, ensuring quality at every step of the way. Fortunately, outsourcing your quality management doesn’t need to be expensive, and there are many benefits that your brand will experience in doing so.

Do you have any questions regarding raw material checks or the apparel industry in general? What raw material review methods have worked for you in the past?