30 years ago if you were to suggest that paper sketches of new garment designs would be going ‘extinct’ by the early 21st Century, or that product samples would exist solely online, fashion brands would say you were crazy. But that future is here now as computer generated 3D modelling hits the fashion world.

If this is apparel brands’ future, let’s look at how 3D virtual sampling for softlines can positively affect your business.

Could Physical Samples Be A Thing Of The Past Soon For Softlines?

Technological advancements and the adoption of 3D models have been prominent in manufacturing and engineering industries for decades, working with products such as furniture, automobiless, computer chips, planes, and more. However, 3D technology has only recently started infiltrating the apparel industry as more benefits of its use are coming to light. It can be used for everything from product design, development, sampling, as well as for the use of 3D images for websites.

This post explores 3D virtual sampling in the apparel industry and discusses how it will impact the production of soft goods, both positively and negatively, in the near future.

What are the advantages of 3D virtual sampling?

One of the most significant advantages of 3D virtual sampling is its ability to speed up the product development process. When it comes to sampling development, 3D technology offers apparel brands the ability to modernize their sample-development processes which in turn saves time and money and helps brands respond quicker to customer trends and buyer demands.

Virtual sampling challenges the traditional ways of product development. Working advanced technology allows designers to make 3D virtual samples of garments, rather than building them physically from real fabric and shipping them to various design houses and manufacturers. This enables brands to increase overall efficiency and lower production costs, all while meeting quality standards and specifications consistently.

Image Source: Tukatech

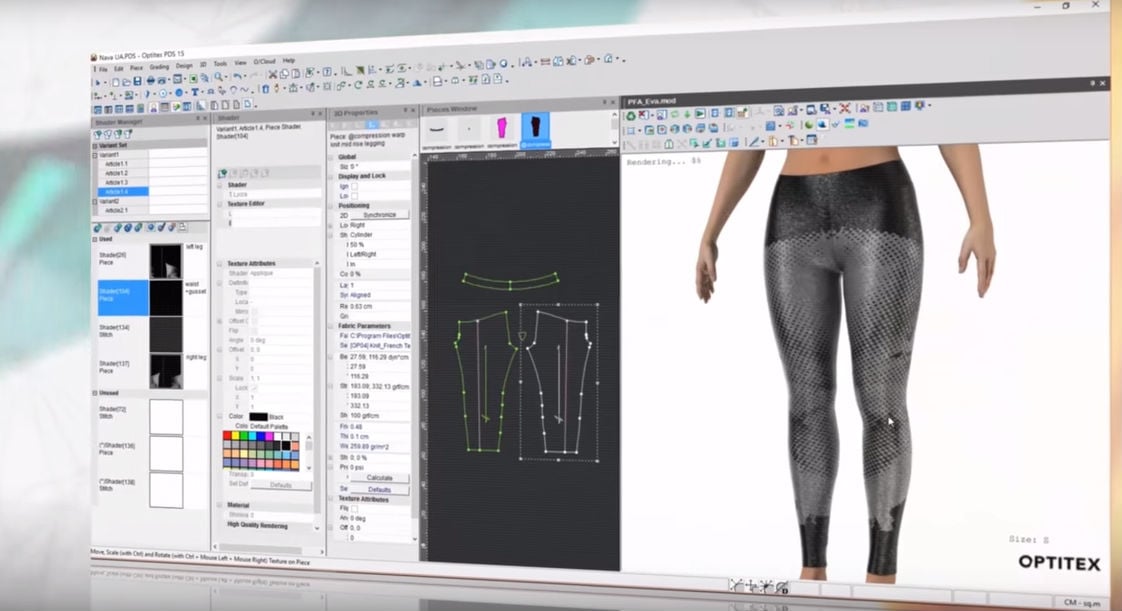

This video below shows a type of 3D sampling software from EFI Optitex being used to produce and on-screen sample, adjusting the size and fit of a garment in both 2 and 3 dimensions:

You’ll notice that making adjustments to the garment is immediately displayed in 3D, so you will see instant changes on screen without needing to make a new sample each time. Interestingly, the software is also advanced enough to be able to display different materials and their unique characteristics, for instance, one fabric may drape differently over the body than another, and this can be displayed for a realistic view.

You may be interested in this other blog post: Production Automation for Softlines: Sewbots Replacing Workers.

Furthermore, designers can save 3D virtual samples of garments as an image and from any perspective using the software. There are no limitations on the colors, prints, sizes, etc. that can be experimented with, which makes it easier for buyers to select the preferred version of the design. The sample can easily be emailed to the necessary stakeholders, which allows designers, fit technicians and executives to assess the sample before it has to be cut and sewn from cloth.

Doing this means manufacturers do not have to spend money and time producing a number of prototypes in different sizes, or using different fabrics, that may never be used.

It can often be found that a garment requires corrections, rework, or adjustments which requires a new version of the product to be cut, sewn and shipped off to the buyer. 3D virtual sampling eliminates the need for physical samples, which can vastly reduce unnecessary time and money spent on rework. Virtual sampling takes care of any necessary changes that need to be made before the garment needs to be sewn, saving on fabric costs, shipping costs as well as model costs. It has the ability to positively impact all facets of a supply chain if implemented correctly.

Image Source: Optitex

According to Sourcing Journal, new virtual sampling technologies continue to enter the market, such as Tukatech’s 3D Fashion and Design Development Software.

Brands such as Under Armour, Target, Coach, Victoria’s Secret, Hugo Boss, Maggy London, Phillip Van Heusen, Nike, Abercrombie & Fitch, and more have already started making use of 3D virtual sampling technologies, while many more brands are expected to do so in the near future.

Benefit Breakdown Of 3D Virtual Sampling For Softlines

- 3D modelling speeds up the production process, taking a concept to production in just weeks instead of months. Apparel brands are under pressure to be ready to go to market before or at least at the same time as their competition, so being able to shave weeks or even months off the design process by avoiding waiting time to create different iterations of samples is invaluable.

-

Computer designed 3D samples use the exact pattern and model’s body measurements to display an accurate representation of the garment’s style and fit

-

Producing a virtual sample takes a short time. Postage of fabrics and samples to and from suppliers to customers, and the waiting time for them to be created by hand and arrive, is all but eliminated.

-

Customers can demand changes to the fit and style of garments at any time and these can be sampled straight away, allowing more production flexibility.

-

Sampling costs vastly reduced. Many samples can be made using different fabric types, textures, colours, and prints; not to mention sizes. Making all of these as physical samples could be cost prohibitive.

-

Computer-generated images of garments can be used in brochures, on websites, and in marketing materials without needing to take photographs of physical samples.

{{cta(‘1a5ca685-6e21-4643-8db6-02b83389302b’)}}

What are some of the challenges of moving away from the physical?

Lack of trust

Are companies ready to embrace 3D samples and exclusively use them to make decisions on soft goods that are to be produced?

Are consumers ready to trust in garments that have been produced based on computer design rather than analogue physical samples?

While traditionalists will need longer to be convinced, when huge companies like Hugo Boss and Adidas have been using 3D design successfully, it makes the case increasingly compelling.

Lack of skills to use 3D design

Credible 3D solutions in the market need patterns to arrive at the final 3D image; however, many fashion companies no longer have internal pattern makers and instead outsource the work by sending off technical packs to their partnering factories who will then create the prototype sample. The challenge is deciding who the development of the 3D content should be tasked out to within the organization. While creative and tech designers exist within a company, they may not have the necessary skills needed.

Expense of being an early adopter

Investing in virtual sampling is expensive, and adoption rates are still currently slow. The success rate will depend on the end-user and whether the consumer will feel comfortable with purchasing from virtual models.

CEO of Optitex, Asaf Landau, speaking in Just-Style, stated:

Companies with turnover of above US$50 million probably have the clearest ROI.

The software can still improve

Lastly, the Avatar still experiences some difficulties regarding personalization and needs to improve on some aspects such as collision detection which will help designers create a garment’s layering effect, which is one of the biggest components missing from virtual garments. That way designers can develop puffs, pleats, padding, etc. that they would in real life.

The Verdict

Larger apparel brands will benefit from and are probably using 3D design right now.

While there are definite benefits which brands can experience from implementing 3D virtual sampling, various challenges still exist. Whether these benefits outweigh the challenges, and whether investing in 3D technology will be worthwhile depends on each brand’s unique goals and challenges.

One thing is certain though, and that is that virtual sampling is inevitable as we move into an increasingly digital world.

How do you think virtual sampling will impact the apparel industry?

Do you have any questions regarding soft goods production?

Leave a comment below, we’d love to hear from you!

{{cta(‘8a802816-7d35-40de-8006-bf8b85537c60′,’justifycenter’)}}