In the age of instant information via the internet, trends, news and information move at an accelerated rate. Moreover, as access to information grows, so has the awareness of the world around us and the impact of industry on human lives and the environment. Due to this increased digital transparency – the global trend for consumers to prefer more sustainably produced and environmentally-friendly products has become widely-noticed by both brands and manufacturers.

Assessing the Need for Standardized Sustainability

With almost daily news reports of organic foods, biodegradable packaging and other sustainability initiatives, the textile and apparel industry has found itself in the mix as well.

The desire of consumers for responsibly produced, sustainable goods is being driven by several factors:

- Awareness: Today’s consumers look to a brand itself to take the initiative and accept responsibility for the environmental footprint they leave. As brand awareness continues to become a more integral part of a company’s image, consumers are looking to the brand as an entity to be accountable.

- Supply Chain Control: As consumer knowledge increases, many retail companies are finding themselves tasked with more than just the sustainability of their product. They are also being tasked to take responsibility for the behavior and performance of the impact of their vendors and their distribution network.

- Fairness: This social aspect of consumerism is not only manifesting itself in sustainable product design, production and distribution; it is also finding its way to the working and health conditions within the manufacturing plants and material processing facilities as well.

With such daunting expectations, many companies are seeking a path to peace of mind over their company’s environmental footprint.

From Patchwork to Process

Traditionally, the process environmental responsibility was a vague patchwork of efforts or in many cases a totally unmanaged aspect of their business.

While the economy became more global in scale and impact, companies still focused internally on what to do to address environmental impact when they focused on it at all.

However, as awareness has increased, many companies within the textile/apparel sphere have turned to a standard approach such as the Higg Index to help them measure their sustainability and that of their supply chain.

The Higg Index provides extensive benefits in adoption to help achieve control and manage their impact for companies wishing to improve and manage their sustainability:

- It has developed global assessment tools and accompanying metrics that allow companies to measure their position and chart a course focused on sustainability while improving processes, production and supply chain management.

- Companies can start from the ground floor with no experience in sustainable initiatives, or they can enter with a high degree of experience from previous programs.

- It allows companies to benchmark themselves within the industry and within like products through standardized metrics.

- The Higg Index can be done modularly for any of its three focus areas – materials, products or brands – and it can be done ‘a la carte’ for those with a specific area of concern.

- It is flexible and perpetually adaptive and updated as new research and technology progress.

Particularly useful for many companies is the Facility Environmental Model 3.0. With the FEM 3.0 companies can perform a self-assessment of their current state of environmental performance and after getting their self-assessment validated by approved verifiers, factories get a verified report with Performance Improvement Plan (PIP) which identifies key areas for improvement. It can also lay the groundwork for the education of factory management, staff and employees as the initiative gains speed.

The FEM 3.0 also includes applicability tests for air, water, wastewater and chemicals to assure that each facility can build their sustainability into their operation with the correct blend of needs.

It is superior to other methodologies because it was developed specifically for the textile/apparel industry and sustainable production from materials to market.

Also, its wide acceptance within the industry means that methods are standardized across the board and metrics are understood by all without having to convert from platform to platform.

Yet, the Higg Index relies on extensive questions to develop a self-assessment allowing a more honest and customized understanding of where they are.

Companies utilizing the Higg Index can expect to year-on-year improvements such as:

- Immediate Impact: The self-assessment starts a process that within three to six weeks can yield valuable, actionable data and information. Using the FEM 3.0 can help a company to develop not only their overall initiative for sustainability but also the procedures for improving their process improvement ongoing to develop the program over the long term, and because the Higg Index is modular and adaptive, companies can join at any stage of the game.

- Improvements Accrue Downstream to the Brand: As the factory moves from self -assessment to verified assessment through the SAC’s Verification Protocol, the benefits of a viable and measured sustainability program can accrue to the brand in terms of consumer perception. It can also help to define what is needed for the brand module of the Higg Index when and if they decide to deploy that module.

- Improvements Accrue Upstream to Vendors: With metrics specific to the textile/apparel industry, companies that previously had little or no internal way to measure progress on sustainability can now begin to define and eventually require, vendor adoption and compliance. In this way, the entire value chain can be laced together in a cohesive sustainability program that allows them to measure their entire supply chain.

Want to learn more about how SgT can assist you to

become to more sustainable?

{{cta(’68ddc48f-35db-4fa6-98d7-c9a99988317f’)}}

Finding the Right Partner

Despite the apparent benefits of adoption of the Higg Index, companies can find themselves overwhelmed with the issues that are identified as self-assessment begins.

To mitigate the fear factor and to provide a methodical and well-mapped path, many companies may choose to use a third-party provider to help them develop their initiative and bridge the gap between self-assessment and full adoption of practices and benefits provided by using the Higg Index.

There are many reasons why a third-party sustainability expert can assist in adoption:

- Time: While the Higg Index lends itself to entry at any level of experience, having a third-party partner with the skillset and experience in testing, auditing and improvement can reduce adoption time for companies who desire to develop a measured program of sustainability.

- A Wider Net: With their finger on the pulse of quality in the industry, a third-party partner likely has not only the overall knowledge of the industry but also of the requirements of the branches and niches within the broader industry. Knowing not only the industry but the company’s specific needs for its specialized product line will assure that the program is customized to the degree needed and that measured results can benchmark progress accurately.

- Professional Expertise: While many companies will have managers, staff and employees willing to pursue true sustainability, they may lack the professional expertise required to engage the problems at the detail level. For many companies, the solutions require completely different methods and processes for tasks that have historically been second nature to them. A third-party partner assisting in the implementation will have access to industry experts and academics at the forefront of research and knowledge about sustainable production.

- Coming to Terms: Using a compliance partner can also allow a company to realize the true shortcomings and obstacles to adoption. This honest assessment enables a path to be charted toward maximizing the benefits.

- Preparing to Succeed: As a company who specializes in quality, testing, verification and improvement, a compliance partner can be that valuable middle piece between the shock and excitement of the self-assessment and the seriousness and best practices that can be established through the use of the Higg Index. They can help bring a company through the initial phase of adoption through to full compliance with a range of services that provide skillsets, insight and interpretation that many organizations don’t possess internally.

Conclusion

As pressure mounts worldwide for more responsible – and responsive – attention from brand names on issues of environmental concern and sustainability, managers and directors in medium to large retail companies should consider the Higg Index.

The gains in process improvement, cost improvement, and traceability alone are highly beneficial.

However, using the Higg Index to develop and measure a company’s environmental impact and develop processes around it is a way to address these concerns while gaining full control over the supply chain, thus doubling the benefit.

For those choosing not to adopt, the consequences could be dire.

Brand recognition and reputation could suffer, and public relations and negative press attention could severely impact the bottom line.

And as the Higg Index is adopted by more and more textile/apparel companies, they may find themselves shut out completely if a large, frontline retail partner requires compliance that the company has not yet implemented and is not prepared for.

SgT is an experienced and capable partner with the industry knowledge, range of services and in-house expertise that can assist companies in achieving the best possible results from the Higg Index FEM 3.0.

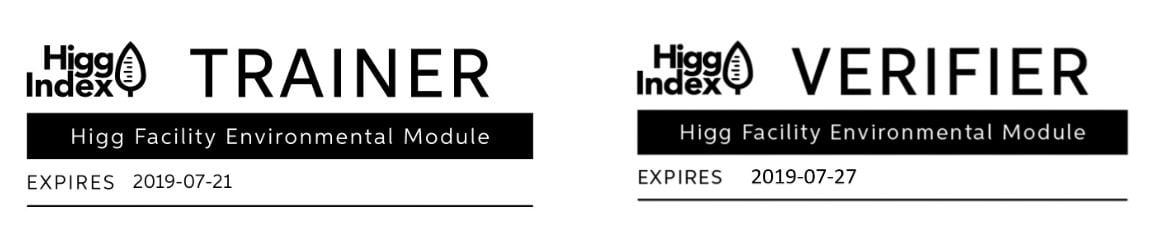

After completion of the required coursework, The Sustainable Apparel Coalition (SAC) has approved a verifier from SgT (Dr. Kannan Muthu, SAC 69) , to offer Higg FEM Training & Verification to facilities that use the Higg FEM.

Just contact us to discuss your situation, for free, with a consultant.

{{cta(‘df2514bd-21b2-4dd1-a2bb-65d0f0235488′,’justifycenter’)}}